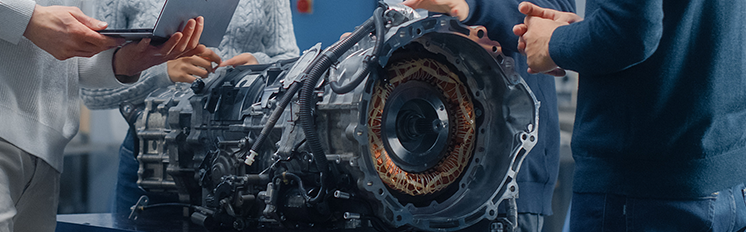

Cut overhead by repairing bearings, motors, pumps, belting and more

Get the most value from your machinery investment. Repairing equipment with superior components cuts costs, improves reliability and supports sustainability. Consider this:

40–60%

savings on repaired or re-engineered components when compared to a new purchase

Partner with CB to extend the life of your equipment and to maximize ROI.

- Cost savings: Allocate savings to other areas of the business, such as research and development or employee training.

- Reduced downtime: Repairing equipment can often be done more quickly than sourcing, purchasing and installing new machinery.

- Sustainability: Repairing equipment reduces waste and the demand for raw materials to manufacture new equipment.

- Extended equipment lifespan: Regular repairs and maintenance can extend the life of your equipment, maximizing return on investment. We use superior components, often exceeding OEM requirements.

- Consistency in operations: Employees are trained to use and maintain existing machinery, avoiding the learning curve and potential mistakes associated with new equipment.

- Depreciation management: New equipment depreciates more quickly, which can impact financial statements and tax liabilities.

- Customization and fit: Remanufactured parts can be built to work with your specific equipment.

Get started today?

How a sawmill saved $240,000 in lost production time

A sawmill with an annual production capacity of $134 million board feet saw its production come to a screeching halt due to the malfunction of a split bearing and housing. A replacement bearing would take 8–10 weeks to be delivered, so the CB RAP team, along with one of their certified repair partners, quickly repaired the defective bearing with a special sealing. This repair saved 24 hours of production time and resulted in a savings of $240,000 for the sawmill.

Certified RAP partners

MoteursPM – PSI – Hydraulique EP – CIFBarsatech – Regal – Groupe EDS – John Crane – Sumitomo – Sew Eurodrive –Rexnord – Timken – Santasalo

Ready to save money and increase efficiency by maximizing the lifespan of your equipment?

How CB helps businesses succeed

Make our Repairable Assets Program work for your business. Add certainty to your operations with CB’s services and expertise for better equipment management across your operation.

Repairing failed assets

Repairing failed assets

Our data-driven approach to rebuilding and remanufacturing often exceeds OEM performance specs. We use superior components and meticulously address all performance issues, ensuring your remanufactured parts integrate seamlessly with your existing equipment.

Online repair visibility

Online repair visibility

Gain easy remote access to your repair history, including frequencies, documented causes of failure, repair status, scheduled delivery dates and all required documents.

Repair vs. replace

Repair vs. replace

Our comprehensive evaluation considers factors such as age, cost, energy efficiency, availability of replacement parts and overall condition. This assessment allows us to develop the best plan for your operational needs.

Assets management

Assets management

We’ll help you develop a long-term asset management plan, creating or updating the asset/component database, and standardizing and consolidating processes. Additionally, we’ll work together so you can reduce energy consumption.

Predictive onsite maintenance program

Predictive onsite maintenance program

Our comprehensive approach includes vibration analysis conducted by ACVM Level 2 technicians, thermographic analysis of equipment and electrical insulation analysis.

Condition-based monitoring system

Condition-based monitoring system

Increase reliability and decrease downtime with a real-time look into equipment performance. We’ll monitor your equipment and alert you to maintenance needs before they become critical issues.

Initiate better performance with our no-risk, complimentary RAP assessment

CB starts by documenting:

- The broken component

- Workflows associated with the equipment

- Cost, process and timeline of repair vs. replacement

The RAP assessment is a no-cost, no obligation process. CB’s experts will provide a recommendation based on our audit, including your estimated cost savings. If you approve our proposal, we’ll get to work. Our goal is to develop an ongoing partnership committed to continuous improvement while supporting sustainability. Rest assured that should you move forward with us, you’ll have visibility during the repairs process via our web portal.

See what our Repairable Assets Program can do for you

- Greater reliability

- Increased availability

- Lower costs

- Increased sustainability